Welcome to the Severn Trent Water Hygiene Newsletter! This month we have three stories, including an in-depth technical myth-buster about closed systems maintenance.

Click here to receive this newsletter in your email inbox each month.

Operations Meeting Success

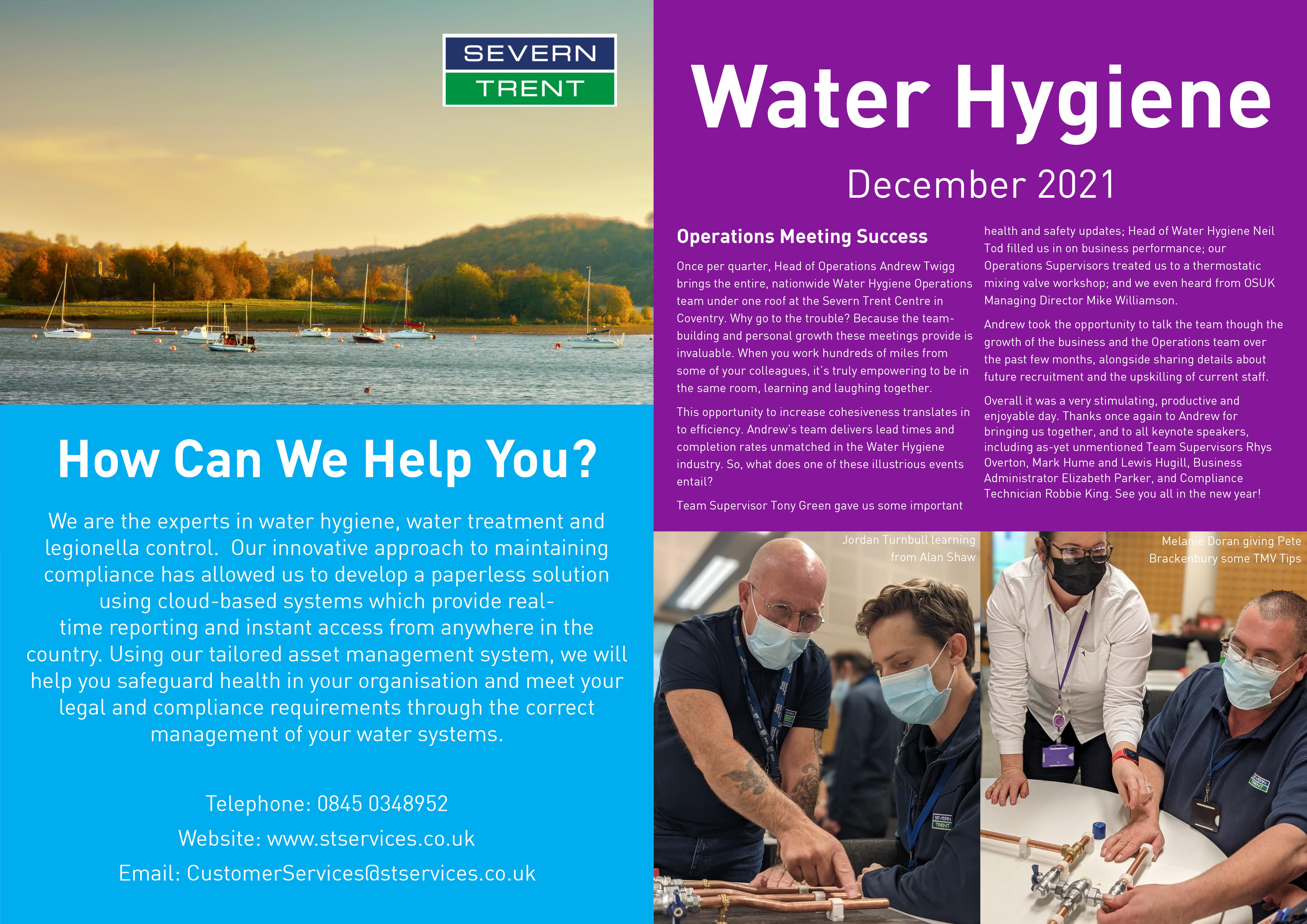

Once per quarter, Head of Operations Andrew Twigg brings the entire, nationwide Water Hygiene Operations team under one roof at the Severn Trent Centre in Coventry. Why go to the trouble? Because the team-building and personal growth these meetings provide is invaluable. When you work hundreds of miles from some of your colleagues, it’s truly empowering to be in the same room, learning and laughing together.

This opportunity to increase cohesiveness translates in to efficiency. Andrew’s team delivers lead times and completion rates unmatched in the Water Hygiene industry. So, what does one of these illustrious events entail?

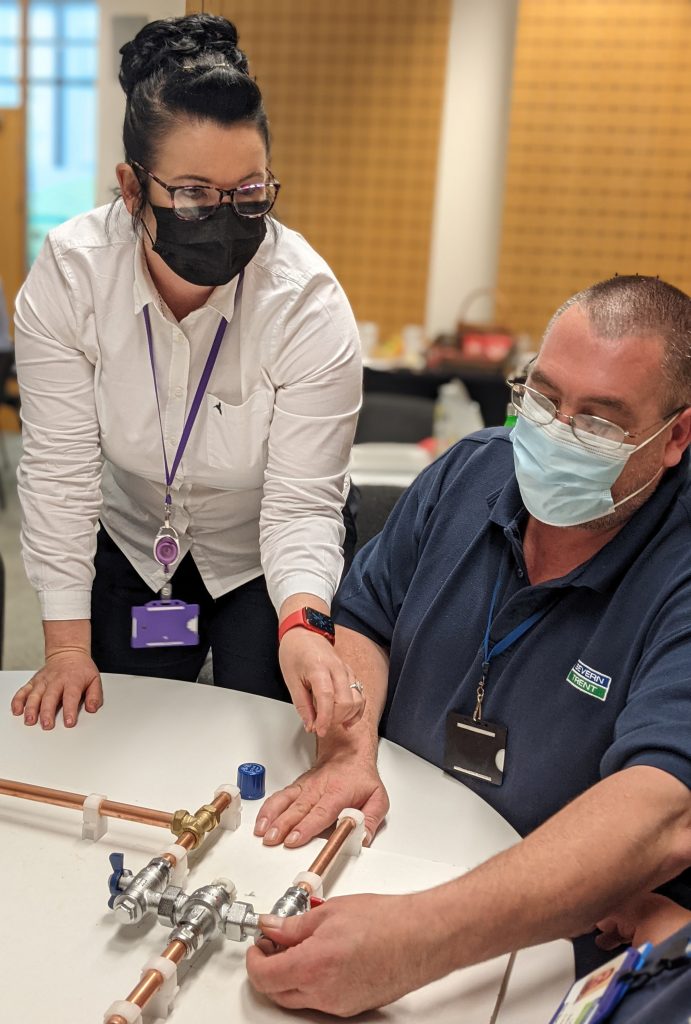

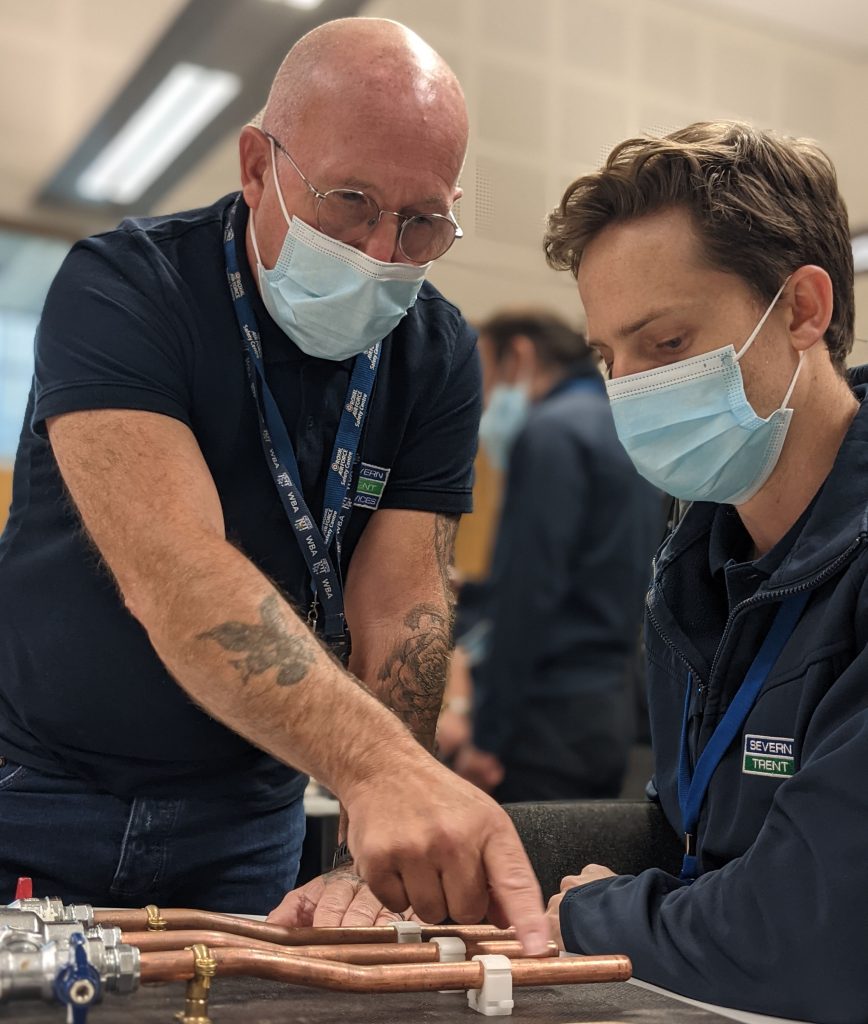

Team Supervisor Tony Green gave us some important health and safety updates; Head of Water Hygiene Neil Tod filled us in on business performance; our Operations Supervisors treated us to a thermostatic mixing valve workshop; and we even heard from OSUK Managing Director Mike Williamson.

Andrew took the opportunity to talk the team though the growth of the business and the Operations team over the past few months, alongside sharing details about future recruitment and the upskilling of current staff.

Overall it was a very stimulating, productive and enjoyable day. Thanks once again to Andrew for bringing us together, and to all keynote speakers, including as-yet unmentioned Team Supervisors Rhys Overton, Mark Hume and Lewis Hugill, Business Administrator Elizabeth Parker, and Compliance Technician Robbie King. See you all in the new year!

Melanie Doran giving Pete Brackenbury some TMV Tips

Jordan Turnbull learning from Alan Shaw

Closed Systems Misconceptions

Caring for closed systems can be a challenging task, however Kris Rowland, our Technical Delivery Manager, has demystified some of the common misconceptions…

Sodium nitrite corrosion inhibitor corrodes Aluminium.

Sodium nitrite, commonly shortened to nitrite, is not corrosive to aluminium, rather it is the pH of the solution that the nitrite is suspended in which causes the damage. This is due to aluminium being an ‘amphoteric’ metal and susceptible to corrosion in both acidic and alkaline conditions, unlike most metals which are stable in one but not in the other. Therefore, any type of corrosion inhibitor can be detrimental to Aluminium should the pH drift outside of 6.5 to 8.5. As such, only corrosion inhibitors specifically designed to be used on aluminium systems should be used, as they will have the correct pH.

All closed-systems require the same frequency of monitoring.

BSRIA identifies that, as a minimum, closed recirculating systems should be monitored on a quarterly basis. It also defines the chemical and microbiological tests required to demonstrate that the system is in ‘good’ control. This does not mean that a system cannot be sampled more regularly. The guidance indicates that, as determined by system conditions, more frequent sampling may be undertaken as often as monthly.

It doesn’t matter how much corrosion inhibitor is present in the system.

Corrosion inhibitors have an operating window of concentration; they need to be kept within a certain ‘reserve’. For example, adding too little or too much nitrite corrosion inhibitor can induce pitting corrosion within the system. In those instances, corrosion has either been started or made worse by the addition of the incorrect volume of chemical. It is vitally important to only add the recommended volume of chemicals to ensure that the correct reserve concentration is maintained. This should be done by slowly circulating the chemical around the system until the desired concentration is achieved.

You can’t take samples when the system is turned off.

Firstly, we need to define the word ‘off’, as this could refer to either the heating or chilling elements being turned off, or the system itself not being circulated. BSRIA indicates that where the ‘heating’ or ‘chilling units’ of a closed system are turned off, the system should still be circulated for at least one hour per day. This is because many corrosion inhibitors do not work effectively in ‘low’ or ‘no-flow’ conditions. Where this is the case then, samples can be taken as the system is circulating the corrosion inhibitor.

The caution given by BSRIA is concerned with the interpretation of sample results from systems where there is no circulation, i.e. where the system has not been circulated for one hour per day. An untrained person may interpret the results as being artificially poor. They then might make recommendations for additional dosing or remedial work. These interventions would not be required and, could lead to potential damage. This is where a robust quarterly sampling plan will aid in the analysis of the samples, as a trend can be established, and unusual results can be clearly identified and interpreted in the correct manner.

All corrosion is magnetic.

The simple answer is no. Closed systems can be comprised of many types of metal, not all of which will generate a magnetic oxide layer strong enough to be removed by magnets. Iron, for example, has three main oxidation states but only iron(III), otherwise known as magnetite, is generally magnetic enough to be removed by magnetic separation. Other iron oxides simply have too weak a magnetic field to be removed effectively.

Coupled with this, the fact that steel systems will likely include copper pipework (which is so weakly magnetic that it is deemed to be ‘non-magnetic’ in practice), which can corrode in similar conditions and cannot be removed by magnetic separation, all systems will generally require another method of removing any build-up of corrosive products. Usually this is in the form of a particle filter which is designed to catch debris of a certain size.

Meet Rebecca O’Sullivan!

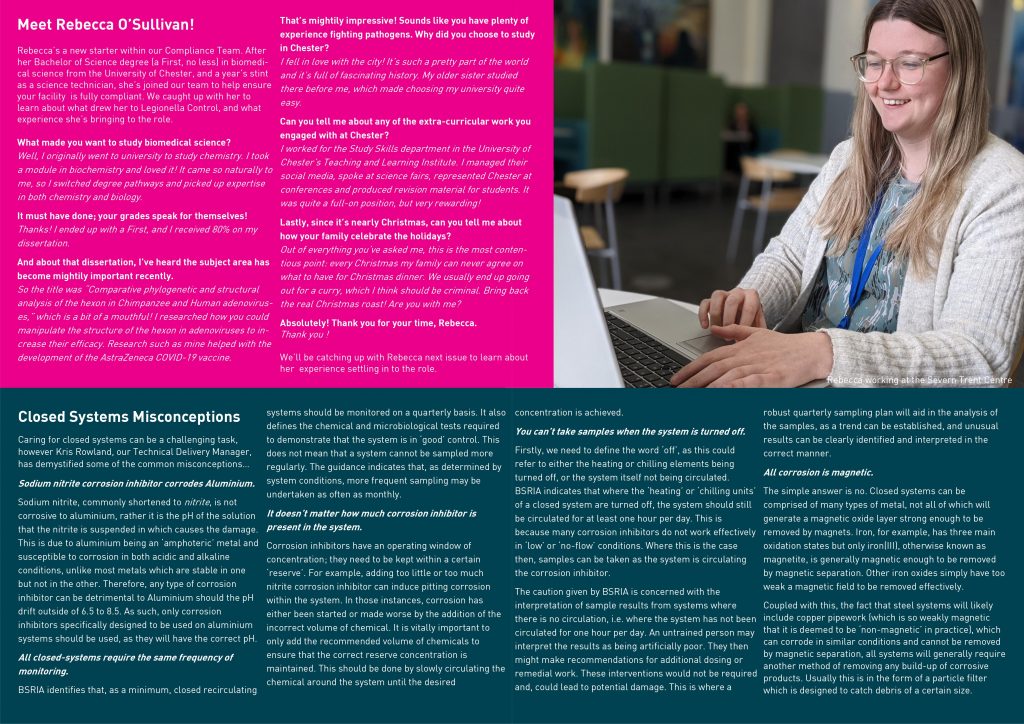

Rebecca’s a new starter within our Compliance Team. After her Bachelor of Science degree (a First, no less) in biomedical science from the University of Chester, and a year’s stint as a science technician, she’s joined our team to help ensure your facility is fully compliant. We caught up with her to learn about what drew her to Legionella Control, and what experience she’s bringing to the role.

What made you want to study biomedical science?

Well, I originally went to university to study chemistry. I took a module in biochemistry and loved it! It came so naturally to me, so I switched degree pathways and picked up expertise in both chemistry and biology.

It must have done; your grades speak for themselves!

Thanks! I ended up with a First, and I received 80% on my dissertation.

And about that dissertation, I’ve heard the subject area has become mightily important recently.

So the title was “Comparative phylogenetic and structural analysis of the hexon in Chimpanzee and Human adenoviruses,” which is a bit of a mouthful! I researched how you could manipulate the structure of the hexon in adenoviruses to increase their efficacy. Research such as mine helped with the development of the AstraZeneca COVID-19 vaccine.

That’s mightily impressive! Sounds like you have plenty of experience fighting pathogens. Why did you choose to study in Chester?

I fell in love with the city! It’s such a pretty part of the world and it’s full of fascinating history. My older sister studied there before me, which made choosing my university quite easy.

Can you tell me about any of the extra-curricular work you engaged with at Chester?

I worked for the Study Skills department in the University of Chester’s Teaching and Learning Institute. I managed their social media, spoke at science fairs, represented Chester at conferences and produced revision material for students. It was quite a full-on position, but very rewarding!

Lastly, since it’s nearly Christmas, can you tell me about how your family celebrate the holidays?

Out of everything you’ve asked me, this is the most contentious point: every Christmas my family can never agree on what to have for Christmas dinner. We usually end up going out for a curry, which I think should be criminal. Bring back the real Christmas roast! Are you with me?

Absolutely! Thank you for your time, Rebecca.

Thank you !

We’ll be catching up with Rebecca next issue to learn about her experience settling in to the role.

Click here to receive this newsletter in your email inbox each month.